The next big things

Four Canadian inventors, and winners of this year’s Ernest C. Manning awards, whose ideas are changing the world

Photograph by Brian Howell

Share

Each year, the Ernest C. Manning Awards Foundation recognizes four Canadians who are developing and successfully marketing homegrown, breakthrough innovations.

For this year’s winners, the awards recognize decades of hard work. Philip Hill started testing green diesel engines in the 1980s; today, he is collaborating with some of the world’s top engine-makers on a design that could revolutionize the transport industry. The Manning Awards also recognize that great ideas don’t just come from the lab. Two of the prizes (the Innovation Awards) go to those who haven’t had access to research facilities or advanced education in their fields. After designing a hands-free device to help a disabled friend better communicate, Randy Marsden, for instance, started a company that is now marketing a keyboard that will make hospitals cleaner and safer. Whether the winners worked doggedly in a lab or the garage, their ideas are having an impact today, not just in Canada but around the world.

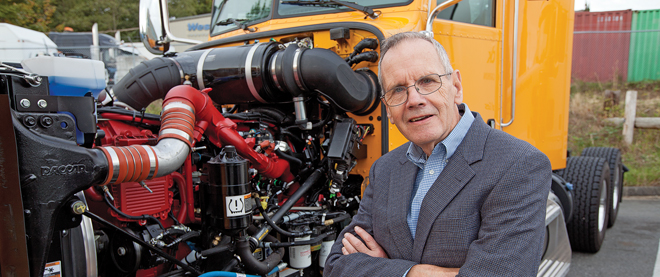

Heavy trucks, light on emissions

Most people think of diesel engines as smelly, dirty and loud—but Philip Hill, a mechanical engineer and retired professor at the University of British Columbia, has spent decades trying to make them cleaner. In the early 1980s, Hill started working on an engine fuelled by natural gas, cutting back on smog and soot; today, vehicles across North America are using natural gas-powered diesel engines developed from his original design.

The transportation industry accounted for 24 per cent of the increase in Canada’s greenhouse gas emissions from 1990 to 2008. Diesel engines are “the engine of choice for heavy-duty applications,” like pulling large highway trucks, Hill says. Some improvements have been made in the last decade, but the engines still tend to spew nitrogen oxides (a component of smog) and soot particles. “Keeping the engine and changing the fuel became the emphasis,” Hill says. But early efforts at alternative fuels for heavy-duty trucks struggled to meet demand for durability, power, affordability and low emissions.

Working with a team of grad students and one single-cylinder test engine, Hill designed his own equipment. Research engineer Bruce Hodgins joined the project, and the team created a means to inject first a small amount of diesel fuel to start combustion, and then the natural gas. This concept, called high pressure direct injection (HPDI), was so successful that, in 1995, a company was launched to commercialize it—Westport Innovations Inc., in Vancouver. “Sometimes it’s easy, in pure research, to just look at the science,” says CEO David Demers, “but Phil was looking at how to do this practically, for society.” Hill serves as a Westport consultant today.

It took five years before Westport’s first dollar of revenue came in, but success quickly followed as the company developed a series of other technologies to fuel engines with natural gas. The technology originally designed by Hill is now operating in everything from bus fleets to garbage trucks and UPS heavy-duty trucks in North America and Australia. Westport collaborates with three of the four biggest diesel engine manufacturers in the world, Hill says, working on natural gas usage in transport engines. The company recently announced a deal with Shell to market liquefied natural gas-powered vehicles across North America.

Focusing on diesel made sense from a commercial perspective, says Demers. “We’re focused on people who use a lot of fuel, because that’s where the economic incentive is highest to switch to a cheaper fuel, like natural gas.” It makes sense from an environmental perspective, too, something Hill recognized decades ago. Back when the company was launched, “he spoke very eloquently about this, and he’s right,” Demers says. “We desperately need a way to move people and goods around efficiently—and we have to do it without oil.”

Using babies to fight bullying

In the opening chapter of her 2005 book Roots of Empathy: Changing the World, Child by Child, Mary Gordon describes the effects of a classroom visit by a mother and her six-month-old baby on a tough-looking boy named Darren, who was bounced between foster homes all his life and enrolled in Grade 8 for the second time. Gordon writes of how, to everyone’s surprise, Darren volunteers to cradle the baby. After a few moments of gentle rocking with the child, Darren looks up and asks: “If nobody has ever loved you, do you think you could still be a good father?”

Gordon has been sending parents and their newborn babies into classrooms across Canada and six other countries for more than a decade. The goal of her organization, Roots of Empathy, is to teach “emotional literacy” by demonstrating the quintessence of love and understanding that exists between a parent and child. The power of this relationship, says Gordon, influences children to become more caring, thoughtful, upstanding adults—in short, to be empathetic. “What Roots of Empathy does is give every child in the classroom the picture of what love looks like,” says Gordon. “It has a huge impact.”

By the end of 2012, more than 450,000 children are expected to have experienced the program. Gordon has been widely recognized for the work, receiving interest from the European Union and the WHO.

Gordon’s program caters to children in kindergarten through Grade 8. A parent and baby visit a classroom nine times during a school year, while a Roots of Empathy instructor drops in separately before and after each visit. Throughout these sessions, children are asked open-ended questions, like: “Do you remember a time when you felt frustrated like baby Carter?” The “bridge to empathy” is crossed when children understand that they share the same capacity for feeling as others, and then care about what those feelings are, Gordon explains.

Roots of Empathy has been called Canada’s best anti-bullying program, something Gordon credits with how the program teaches children to emotionally identify with their peers, and to stand up for them when they’re getting picked on. “That’s what empathy is. They jump in when there’s an injustice, and they jump in when they can make something better,” she says.

Prepping the hospital computer

Keyboards are the toilets of the cubicle. They gather bacteria and, with their little notches and tiny gaps, rarely let it go. In the office, that can be a hassle—you might catch a flu from your keyboard. But in a hospital, where antibiotic-resistant germs hover in the air, it can be deadly.

Which is where Randy Marsden comes in. Four years ago, Marsden’s Edmonton company developed a touch-screen keyboard designed for easy cleaning. The Cleankeys board has a single, easy-to-wipe surface. In a trial performed by the University of Alberta, it proved 100 times cleaner than a traditional keyboard after a simple scrub. Cleankeys is already popular with dentists, especially in Europe. Now Marsden is hoping hospitals adopt the technology, too. Right now, a Calgary hospital is studying Cleankeys on a special unit.

Marsden came to his current vocation by accident. Twenty-two years ago, as a student at the University of Alberta, he designed a hands-free device to help a paralyzed friend better communicate. The product essentially transformed a computer into a speech aid. After graduation, Marsden founded a company to market it. And for more than two decades, as president and CEO of Edmonton’s Madentec Ltd., he has developed new technology products that help the disabled.

A few years ago, Marsden made an unlikely pivot. One of his products is a head-tracking camera that allows disabled users to move a cursor across a computer screen. It became, quite accidentally, popular with another customer: a dentist. The dentist had a digital X-ray system in his office. But every time he wanted to use the mouse, he had to take his gloves off. The Madentec camera allowed him to skip that step and avoid any risk of contamination. At first, Marsden was “happy to have another market,” he says. But, eventually, he started thinking about what problem, exactly, the camera was solving.

To find out, Marsden convened a focus group of dentists and discovered they were going through all kinds of hoops to keep their computers clean. They “were stuffing [the keyboards] in plastic bags, wrapping them in Saran Wrap,” Marsden says. He figured there had to be a better way.

Marsden debuted the first Cleankeys prototype at a dental conference in 2007. He sold 4,000 units right away. With a new model now in mass production, Marsden is hoping to see orders come in from all over the world. “One of the most contaminated surfaces in the hospital is the keyboard,” he says. With Cleankeys, that might change.

Seeing clearly through the spray

Sometimes inventions spring not from sleek and sterile labs in the big city but from a garage in northern Ontario. Very frequently, these gizmos have troubled beginnings—such are the travails of the small-time inventor. Consider the tale of the Morins, Albert and Mark, an intergenerational affair. Their story begins one rainy day in the mid-1980s, when Albert and his wife, Muriel, left Toronto and headed north for Sudbury, Ont., where they lived.

Albert, a construction worker with a Grade 8 education, was also an inventor who tinkered in the garage with reams of patents to his name. After a frustrating business meeting involving a revolutionary snow-melting machine Albert had designed, he and Muriel found themselves caught in the heavy spray of the trucks lumbering north through a storm. “I’d duck every time we’d pass one,” says Muriel, who remembers turning to him and suggesting he invent “something simple”—a thingamajig to cut down on all that horrible spray. “That’s all it took,” she says.

He didn’t sleep much that night. Drawings progressed to cardboard cut-outs, which became a plastic prototype. Soon Albert had invited Muriel to the garage and, with a spray bottle full of water and her hair dryer, demonstrated how it worked. The idea used louvres to create a pocket of negative air—a vortex—that would suck water off the tires.

Mark, Muriel’s son from a previous marriage, saw the new invention and was transfixed. “I wanted to be a part of it,” he remembers. Albert patented his new invention and then, at age 59, died. His mud flap probably would have died too—except that, 10 years ago, Mark lost his job at Union Gas. He’d long been thinking about his brilliant step-father’s mud flaps. “We just felt it was a door that was being opened,” says Shelley, his wife.

She and Mark, who live in Restoule, Ont., near North Bay, launched Vortex Splash Guards in 2001, persuading Engineered Plastics Inc., a U.S. firm, to manufacture the device. “It suppressed about 80 per cent of the spray coming off big trucks,” says Denny Scalise of Engineered Plastics. The newfangled mud flap started strong, with Volvo Trucks including it on a futuristic truck-of-tomorrow it was exhibiting. But there were setbacks: an opportunity to sell to the U.S. Department of Defense went nowhere after the Morins got a bad batch from the manufacturer, causing a failure during a crucial test. And they could be a hard sell—at US$32 for a set of two, compared to US$20 for traditional flaps. “Everyone who sees it loves it,” says Scalise. “Then when they go to stroke a cheque, it just never happens.”

Mark took matters into his own hands, designing a version for recreational vehicles and licensing it to a Kansas firm. And he got Canadian Tire interested in the same design—though a homemade variety. The Morins assembled manufacturing parties out in their garage, inviting family to cut semi-truck mud flaps shipped from Pennsylvania into sizes suitable for pickups and RVs. Canadian Tire dropped the product. “We’ve definitely had our ups and downs—the financial strain and everything,” says Shelley, who has two adult sons with Mark. “We’ve just basically invested our lives into it.”

Still, Mark hasn’t given up and says tests show the Vortex reduces drag and generates significant fuel-consumption savings for a smaller carbon footprint: “It’s enough to change the face of mud flaps as we know them!” He’s unflappable, a salesman so entranced by Albert’s design he can’t stop selling. “He’s my hero,” says Shelley. “Honestly.”